What Is CFD, and Why Does It Matter for Creating the World’s Best Waves?

When you hear “CFD,” you might think it sounds like something only aerospace engineers or Formula 1 teams would care about—and you’d be right, but that’s exactly why it matters for us too.

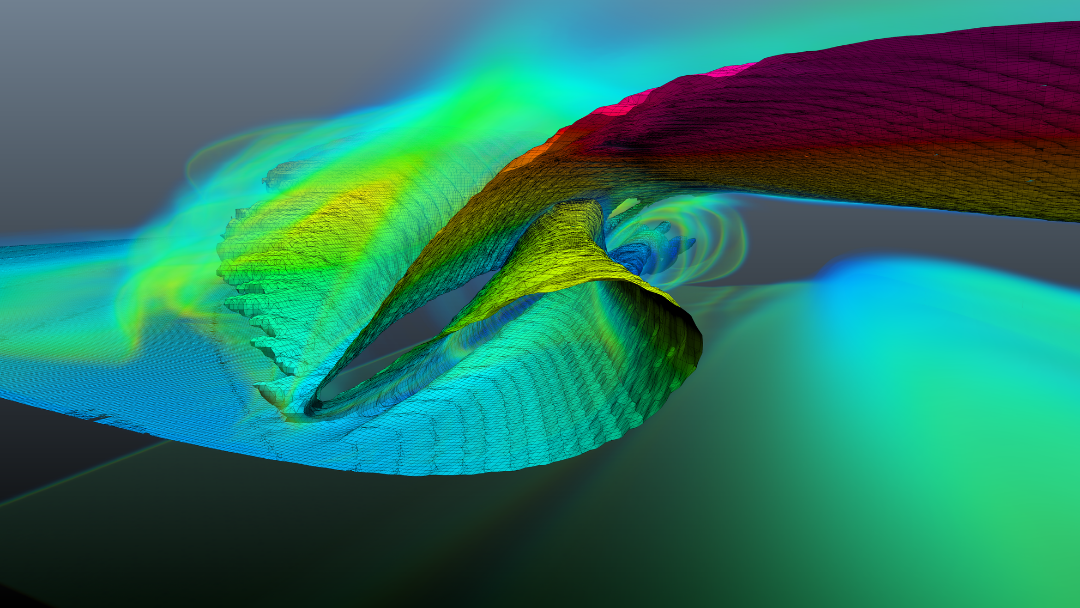

CFD, or Computational Fluid Dynamics, is a powerful tool that uses advanced computer simulations to predict how fluids—like air or water—flow in real-world conditions. It’s the same technology that helps engineers design aircraft wings for maximum lift, race cars for peak aerodynamic performance, and even skyscrapers that can withstand hurricane-force winds.

In Formula 1, CFD is used obsessively to shave milliseconds off lap times. Entire teams of engineers run millions of simulations to optimize every curve, wing, and duct on the car—long before they ever test it on the track. In aerospace, companies like Boeing and Airbus rely on CFD to test wing shapes, fuselage aerodynamics, and fuel efficiency without building countless physical prototypes. Even the renewable energy industry depends on CFD to design wind turbines that squeeze every bit of energy out of each passing gust.

So, what does all this have to do with surfing?

At Crest, CFD is at the heart of how we design and perfect our wave-generating systems. Our Chief Technology Officer and Partner, Alex Poirot, pioneered the use of CFD in surf park design between 2008 and 2014—long before it became the industry standard. Back then, Alex applied these advanced techniques to help create the Kelly Slater Surf Ranch, one of the most iconic and high-performance artificial waves ever built.

CFD allowed Alex and the team to simulate exactly how water would move through the complex wave-generating machinery and shape the resulting wave face with near-perfect accuracy. When Surf Ranch opened, the real-world waves matched the computer predictions with remarkable precision—a testament to the power and reliability of CFD when executed by experts who truly understand both fluid mechanics and surfing.

Here at Crest, we’re building on that proven legacy. Under Alex’s leadership, our engineering team uses the same advanced CFD modeling to design our proprietary wave technology. We simulate countless scenarios to fine-tune everything: water flow, air pressure, chamber design, and the intricate timing that shapes every crest, barrel, and peel. This ensures our system delivers consistent, customizable, high-quality waves while minimizing energy use and maximizing efficiency.

Just like a Formula 1 car wouldn’t hit the track without first being perfected in a virtual wind tunnel, our waves don’t hit the water without first being perfected in the digital realm.

And it doesn’t stop there—our CFD results are rigorously validated through physical scale modeling and third-party reviews to ensure the final product performs exactly as designed. That’s how we can promise surfers the most reliable, high-performance waves—again and again.

For us, it’s not just about building waves. It’s about applying the same scientific rigor that drives the world’s most advanced machines to an experience that’s pure, natural, and endlessly exhilarating. CFD makes that possible—and at Crest, it’s one of the many ways we’re redefining what a surf park can be.